Rolla-V Dies

Rolla-V dies are the best solution for parts with short flanges, tapered cuts or slots near the bending area.

These dies reduce marking on sheet-metal and can offer custom solutions for impossible deep box parts

Rolla-V Fix type

Check out this short video showing the advantages of using the dies with the rollers!!

Adjustable RVM Dies

Testing results on slots present on the bending line.

Check out result at the end of the video

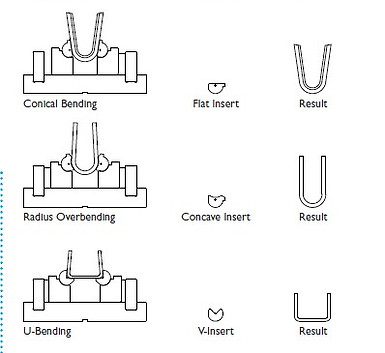

Different inserts for adjustable Rolla-V

Using different inserts we can obtain results that are not thinkable with standard tools.

Pac-man style Rotors

Testing results on a deep box forming

Any adjustable rollaV die is suitable for a pac-man rotor.

This solution allows for deep U shape forms in a single stroke. By simply replacing the upper tool insert we can obtain different U base lengths

180° bend with Rolla-V

Bull nose part bending

They had to tilt the adjustable die in order to fit the part. But most important check how with custom rotors the Rolla-V die fabricates 180° bend

Adjusting the V opening

Adjust the opening

To allow for different thickness fabrication or to enlarge the radius on a part.

Adjustable RollaV dies come really handy on plate and odd part forming

Choosing the correct ROLLA-V die

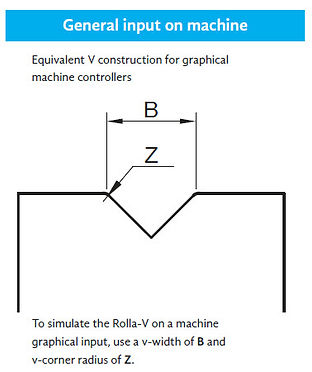

How to Input on CNC & Calculate the force needed

The following tables give us the instructions on how to correctly simulate a standard V on the CNC when using a fix Rolla-V.

We can not explain to the CNC that the flat inserts will rotate once we push on them, so we need to tell the machine there is an actual V on the brake.

This means that we might need to lie to the CNC on behalf of the flange, which the software will think it's going to fall in the V. We need to check on the min. flange value for each model on the above chart. If we are over that value, we're good.

There's also some difference on the calculation of the pressure needed. The formula is here below.

Maintenance and Lubrication

RollaV dies need you to take care of them.

Blowing air on them and lubricating them once a week is good way to keep the tools working for a long time.

Every now and then take the springs out and clean them. You need to unhook them from the bottom and ... well... check the video below

Transfer table for rollaV heavy dies

a MUST HAVE to save yourself from back pain!!